The mechanics behind concrete Undercut Anchors

There are various types of post-installed mechanical anchors but undercut anchors are by far the strongest and able to resist much higher loads compared to mechanical expansion anchors. This is why they are often used in structures such as the nuclear power plants, where human safety is of utmost importance and failure often has catastrophic consequences.

In general, the suitability of the concrete to resist the transfer of the action load from the application is usually decisive. “Concrete capacity” A fixing can only be as good as the base material it is fixing in to. However, how the mechanical anchor transfers the action load has a significant impact on the concretes capacity to resist the load or action.

How Undercut Anchors Work

Mechanical expansion anchors work, as their name suggests, by expanding in to a pre-drilled hole in to the concrete. The friction created by that expansion is what provides the resistance to the tensile action. In general terms, the greater the tensile action, the greater the horizontal expansion forces that are required. High expansion forces create high compression/stress zones in the concrete which detrimentally effects how the concrete is able to resist the action loads.

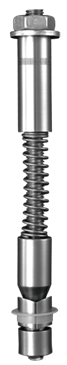

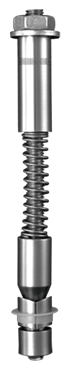

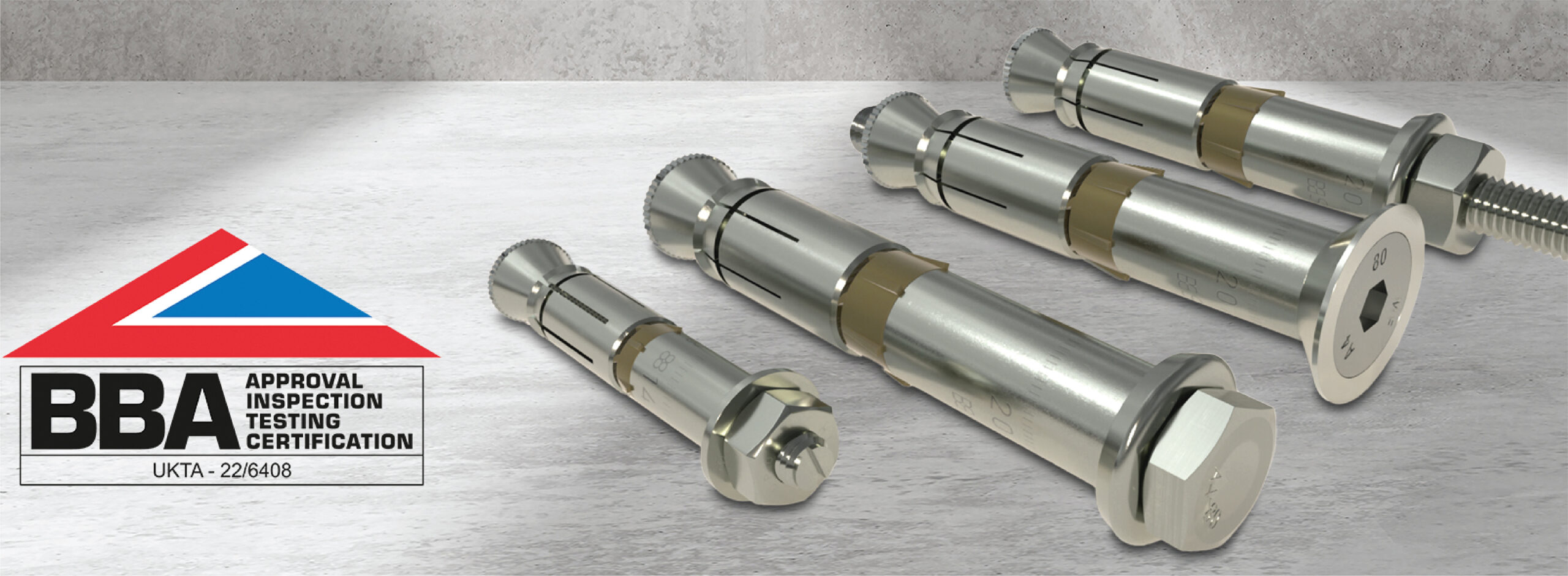

An undercut anchor works differently. It works by creating a positive key in to a pre-cut or self-cut void inside the concrete. They either open out in to a pre-cut void as in the case of the LIEBIG Ultraplus, or they create their own void and key in to that, as in the case of the LIEBIG Ultraplus BLS anchor. They do not rely on expansion and friction and thus they do not create such high compressive or stress zones in the concrete. As a result, undercut anchors are able to make much better use of the concretes capacity and thus are able to resist much higher tensile loads. In addition to normal tensile action loads, the positive mechanical interlock and the reduction of compressive stress zones in the concrete make undercut anchors more able to manage the action loads which are created in dynamic, seismic, shock and other such high impact application conditions.

Undercut anchors perform very well in cracked and non-cracked concrete. They are able to do this due to the positive keying action which is created when they are installed. Positive keying enhances their ability to maintain their resistance as a crack in the concrete expands or is created. Unlike mechanical expansion anchors which require significant follow up expansion capability.

This explains the popularity for the use of undercut anchors on structures located in earthquake prone areas or where seismic qualification is a consideration.

It was discussed previously that the way undercut anchors transfer the tensile action in to the concrete and enhance the concretes capacity to resist the tensile actions, offers significant increased load capabilities. This principal of operation also brings additional benefits. Lower compressive / stress forces in the concrete, means that undercut anchors in general can be used closer to the edges of concrete and can be installed closer to other similar types of anchors. This allows for smaller baseplates, reduces materials and thus resultant cost savings in overall installation costs for an application.

Installation differs depending upon the type of undercut anchor being used.

For a self-undercut anchor like the LIEBIG SUPERPLUS BLS, there is no need for special tools. The undercut is created by the anchor itself. When the BLS Anchor is expanded in to a pre-drilled hole, keys at the bottom of the expansion shield create voids at a predetermined depth inside the concrete. Those keys then lock in to those voids and provide the resistance to tensile action.

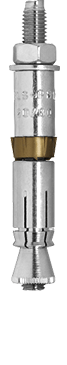

In the case of the LIEBIG Ultraplus, a special tool is used to create a void at a predetermined depth inside the concrete. The spring action of the Ultraplus anchor when installed, forces keys to expand into the pre-cut void. This is how the resistance to tensile action is created using this type of anchor.