LIEBIG anchors ‘bridge the gap’ in Third River Crossing bridge project

From Barnsley to Great Yarmouth via New York!

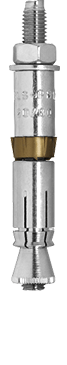

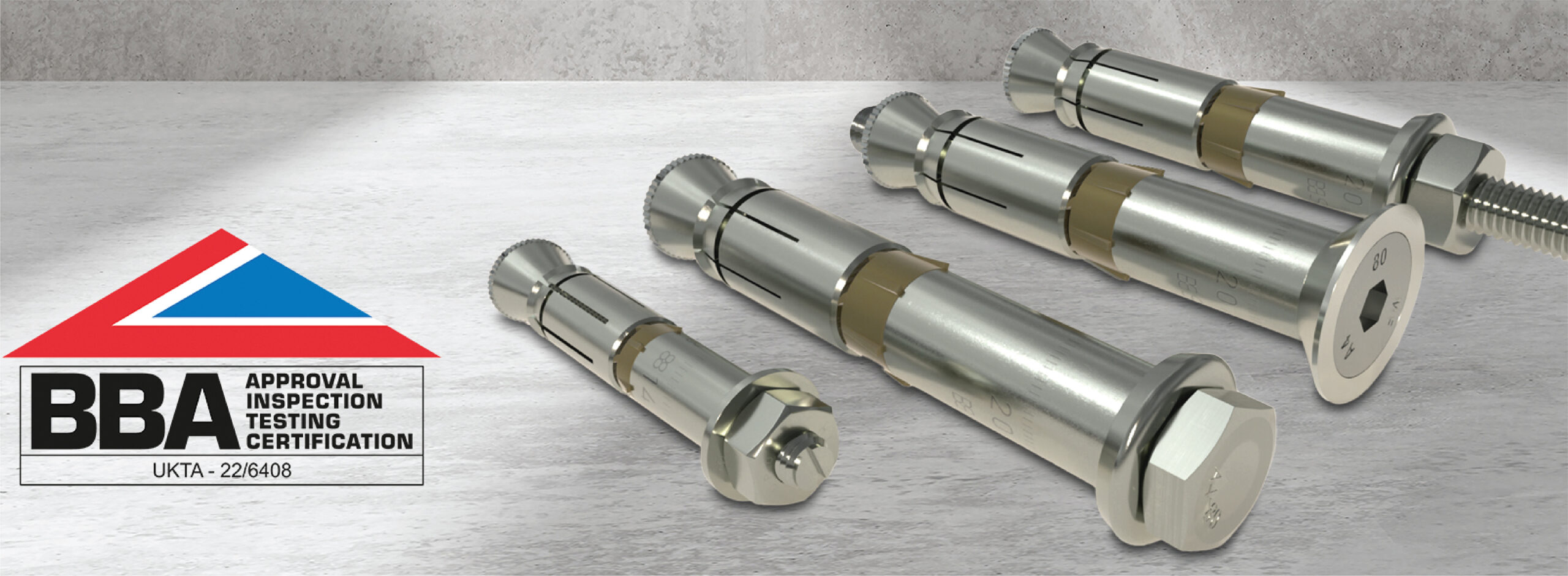

Heavy duty LIEBIG Ultraplus undercut anchors, which are believed to be the largest mechanical anchors ever used in a civil engineering project, have played a key role in the construction of a bridge in East Anglia.

Constructed by BAM Farrans, the new £121m Herring Bridge over the River Yare in Great Yarmouth is set to be a catalyst for investment and development in the coastal town.

The double bascule bridge was designed by globally renowned infrastructure engineering specialists Hardesty & Hannover, based in New York. Their design features cofferdams on both banks of the river to house the machinery and mechanisms required to lift, hold and lower each leaf of the bridge, and it was here where LIEBIG heavy duty anchors were deployed.

Working with bridge design specialists Roughan & O’Donovan (ROD) and project engineers Qualter Hall, the team identified LIEBIG Ultraplus from EJOT UK, as the only genuine undercut anchor that could offer a post-installation solution for this high load application. Due to the complex nature of the project and to keep the schedule on track, a post-installation approach was preferred over cast-in anchoring and the LIEBIG solution satisfied engineers that it would comfortably meet the demanding performance requirements.

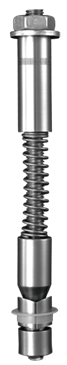

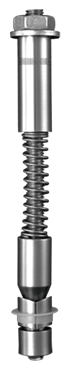

A series of these mechanical anchors were installed in lengths of 1.09m and 1.45m with an M36 diameter after the hole preparation by drilling specialists Core Cut. A mix of the two anchor lengths were used on the same baseplates in an unconventional yet successful approach, securing eight baseplates in total – four on each side of the river. Two baseplates on each side of the river were mounted into the “lower” clevis to secure the lifting and lowering hydraulics.

The mechanism also features tail locks. These secure the turnbuckles that hold the bridge in its ‘raised and open’ position for prolonged periods, and are designed to take loads in excess of 192 tonnes per plate (384 tonnes total) per side.

Once completed the under-baseplate grout will be poured.

Explaining how this mix of anchor lengths provided the solution, EJOT UK’s anchoring specialist, Paul Papworth said:

“Whilst the ETA (European Technical Assessment) for Ultraplus does not legislate for using different lengths of anchor in the same baseplate, the ACI (American Concrete Institute) Building Code does because it takes into account the additional area of resistance in the concrete which can be created by the approach. This meant our anchor specification, in conjunction with our advised redesign of the baseplate which allowed increased concrete capacity to be achieved, would be approved using a combination of different design codes.”

The project was not without its challenges, largely due to multiple components coming together ‘when ready’ rather than ‘when scripted’. Any problems which arose during installation, however, could be resolved collaboratively without adversely affecting the build schedule or budget.

In addition to the very large anchors used to secure the operating machinery, a series of smaller M16 and M20 LIEBIG Ultraplus anchors were deployed to attach the bridge deck’s metal transition plates.

BAM’s Section Engineer Chris Griggs was impressed by EJOT’s ability to provide onsite support and guidance to achieve the correct application of these critical elements.

Chris commented:

“Paul and his team raised the bar on this project in terms of what we should expect from our anchoring partner, particularly in terms of the toolbox talks and availability onsite to solve any problems throughout the process. It was good to be involved in a project where the anchoring ‘experience’ was refreshingly different, and we have so many positives to take away and apply in our future projects.”