Exploring Anchor Types and Their Roles in Bridge Construction

Common Anchoring Techniques in Bridge Construction

Bridge construction requires a range of anchoring techniques depending on the bridge’s design. Every bridge construction project is different, of course, even where two bridges share the same design concept, and a variety of anchor types may be required in a single project to ensure all the structural objectives are met effectively.

But what are common anchoring techniques in bridge construction? Whilst there are several anchor types which are often used, the exact choice very much depends on the type of bridge under construction. For example, a cantilever bridge will have very different requirements to a suspension bridge, and these may differ again compared to a bascule bridge or a swing bridge.

The surrounding ground conditions, bridge usage and local environment will also determine which anchoring techniques are required for the bridge construction.

Common Anchor Types Used in Bridge Construction

Innovation in anchor design means that engineers are able to deploy a variety of anchors in civil engineering projects of all kinds to achieve the stability and structural integrity required. These include:

Pile anchors or vertical ground anchors

These are a deep foundations that transfer loads in multiple directions and are used in construction to resist forces like uplift, wind, and earthquakes. They are typically embedded in concrete and can be used in applications such as offshore moorings, basements and tunnels.

Suction anchors

Also known as a suction pile, suction caisson, or a suction bucket, suction anchors comprise of a fixed platform anchor which is usually used to secure structures into the seabed. They take the form of a long steel cylinder topped with a pile top or cap, with the cap featuring valves to assist with embedment along with the necessary connections to suit its anchoring use.

Gravity anchors

Less commonly used in bridge construction, a gravity anchor is a heavy anchor that uses its mass to secure an object to the seabed. This is why they are more commonly used for deep-sea platforms and floating offshore wind turbines, and are most suitable for stable, rocky or sandy soils, rather than loose soils.

Tension anchors

Tension anchors work by transferring tension from a steel tendon to a structure. They are commonly used in post-tensioning systems and cast into concrete.

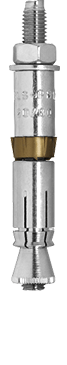

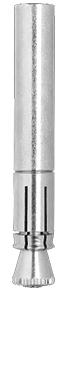

Expansion anchors

Expansion anchors work by grip into a substrate – i.e. concrete or masonry – to secure an object in place. They expand into a pre-drilled hole to create strong holding power thanks to an expansion point which grips firmly against the substrate as torque is applied. There are various terms used to describe this type of anchor including wedge anchor, sleeve anchor, throughbolt and shield anchor.

Cast in anchors

A cast-in anchor is a bolt installed into wet concrete so that it is securely held in position when it sets. The process for installation involves placing an anchor bolt into the foundation and filling the foundation with wet concrete leaving the thread of the anchor bolt exposed above. The high tensile strength and great embedment lengths possible with cast-in anchors makes them ideal for use in foundations.

Material Selection and Durability

Two of the most important considerations regarding bridge anchoring design are durability and geotechnical conditions.

The material selection – i.e. the metals, alloys and composition of the other components in the anchor – must be able to withstand the environmental conditions in which the anchorage is required. These must be assessed in conjunction with the geotechnical conditions at the bridge site to determine the physical properties of the ground and soil at the specific locations.

The Impact of Materials on Anchor Longevity

One of the key questions that arises at an early stage of the anchor specification process is ‘what role does material selection play in anchor durability?’. To answer this question, it is important to understand how different types of metals and other materials react when subjected to long term exposure in demanding environmental conditions.

A key consideration is the level of corrosion resistance offered by the metals. Stainless steel is less prone to corrosion resulting from moisture (rusting) than carbon steel, but both types of steel can be used in anchor components.

It is also important to think about the maintenance requirements of the anchor design. What is the scope for regular maintenance throughout the design life of the anchor design or the bridge itself? How can this be achieved and at what cost, financially and in terms of disruption to the daily operation and use of the bridge.

Environmental Considerations in Bridge Anchoring

As with every construction project, all aspects of a bridge design should be subject to a lifecycle assessment, and that includes the impact of the anchor design and specification. But how is environmental impact assessed in bridge anchoring projects? It could include looking at factors such as:

- Origin of the anchor’s raw materials.

- Manufacturing processes and waste minimisation.

- Durability of the anchorage – how long the anchors will last in-situ before the need to be serviced or replaced.

- Process used for the anchor’s installation.

Ultimately, a key goal at the design and specification stage is to determine the most sustainable anchor design for the bridge construction overall. This will enable the project team to optimise sustainability practices rather than compromise their efforts.

Risk Assessment and Load Distribution

In every type of bridge design, the anchoring approach must provide the necessary load distribution within the foundations. This can be assessed in conjunction with structural engineers who will carry out a risk assessment and the necessary calculations to advise on whether the proposed anchorages will meet the loads or may need to be designed differently.

Types of Anchors in Bridge Construction

Ultimately the types of anchors used in a bridge construction project will vary hugely. But as this article has highlighted, there are a number of common issues and challenges that can be overcome by choosing one type over another. And it may be that applying some creative thinking rather than sticking to the accepted approach based on previous projects, could pay significant dividends.

Innovative Anchoring Solutions: Case Examples

One of the easiest ways to understand the benefits of innovative anchoring solutions is to explore projects in which they have been used. So, to answer the question ‘what are innovative solutions in bridge anchoring?’ we can learn a lot from recent projects as well as those that have stood the test of time over decades and even centuries.

Case Studies: Successful Bridge Anchoring Projects

How do case studies illustrate successful anchoring in bridges? In short, they provide clear evidence of the deployment of anchors in successful projects in a way that other marketing materials cannot. That is why any bridge anchor design case study can inspire and inform the direction of future projects, supporting a wide range of design goals and project deliverables.

It can be really valuable to see the impact of a specific anchor approach for a bridge construction project. And there is an excellent example of this in the LIEBIG case study regarding the Herring Bridge project, a double bascule bridge constructed in 2023 in Great Yarmouth.

Design Optimization and Project Management

Why is design optimization important in a bridge anchoring project? As the Herring Bridge project demonstrates, the choice of anchors can greatly impact on design time and the construction schedule.

Given that this is a bridge featuring cofferdams at either side of the river, the initial approach to anchor the machinery required for lifting, holding and lowering the two leafs was to use cast-in anchors. This would have provided the durability and handle the extreme loads effectively. However, using cast-in anchors on this project would have extended the design time and delayed the construction schedule in comparison to a post-installation anchor design.

The challenge in this project was to establish if there was a post-installation anchor approach that could accommodate the loads without lengthy lead times or significant cost implications.

Stakeholder Engagement and Regulatory Compliance

The task of identifying a post-installation anchor suitable for Herring Bridge involved the architect collaborating with the consulting engineers and bridge construction specialists. Cumulatively, they had extensive experience of delivering bridge construction projects and the standards and regulations that apply.

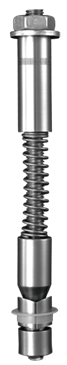

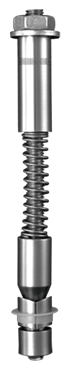

Having identified the LIEBIG Ultraplus heavy duty undercut anchor as a possible solution, the next step was the establish if it could accommodate the loads and comply with internationally recognised standards. Here, EJOT UK’s team was able to assist by providing satisfactory evidence that the use of possibly the largest mechanical anchors ever used in a civil engineering project would be compliant, effective and practical.

The main contractor, BAM Farrans, and the client, Norfolk County Council, were satisfied with the recommendation to use post-installation anchors based on the fact that the approach complied with standards published by the American Concrete Institute (ACI), even though it was outside the scope of the ETA associated with LIEBIG Ultraplus.

Construction Challenges and Solutions

What the Herring Bridge project highlighted extremely well was how the project team was able to apply creative thinking to meet the construction challenges identified in the anchoring risk assessment. A cost analysis revealed major advantages to choosing LIEBIG Ultraplus anchors instead of cast-in anchors and this was another reason why the mechanical anchoring option was given the green light.

Addressing Construction Challenges through Project Timeline

Throughout the Herring Bridge project, the EJOT UK team supported the architect, engineers and contractors to maintain effective stakeholder engagement and to ensure compliance with all regulations. This support was a crucial dimension to the project’s quality control procedures and vital in maintaining safety standards for the lifespan of the bridge.

EJOT’s anchoring specialist provided his expertise and real time experience of post-install application projects throughout the Herring Bridge project, which included problem solving in situ and toolbox talks prior to and during project timeline. The methodology enabling accurately aligned holes, necessary due to the close anchor spacing, was achieved through joint collaboration and team work.

EJOT’s problem-solving assistance was instrumental in keeping the project on track, particularly in relation to the scheduling gap between the hole drilling and delivery of baseplates. Given that coordination of these two events was not possible, to avoid a delay EJOT worked with the other project partners to create templates so the holes could be drilled ahead of the arrival of the finished baseplates.

Another challenge addressed was the positioning of the baseplates on the lower clevis. These had to be mounted at an angle in order to correctly support the hydraulic lifting and lowering mechanisms of the bridge decks, as well as the tail locks that hold the bridge in its ‘raised and open’ position. Here, there was no margin for error, with 100% precision needed in terms of positioning and levelling.

Additional assistance provided by EJOT to bring this ‘outside the box’ anchoring design to fruition was the provision of a special length undercutting tool. This enabled the creation of the required undercut to a depth of 1300mm or more.