ULTIMATE STRENGTH, ULTIMATE SOLUTION!

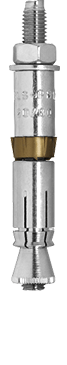

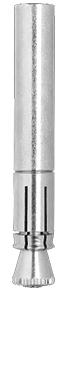

When EJOT became custodian to the LIEBIG anchoring range, the Group’s manufacturing portfolio expanded with the physical size of LIEBIG anchors adding a new dimension – notably, the ULTRAPLUS undercut anchor.

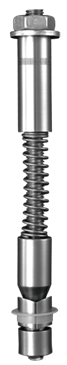

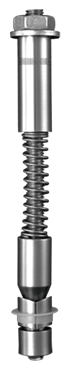

The LIEBIG ULTRAPLUS design offers the highest tensile and shear performance of any other undercut anchor on the market, from 320KN tensile load and beyond, so it is easy to appreciate why structural engineers all around the world respect this unique anchoring technology for the most critical applications.

So… how Big is BIG?

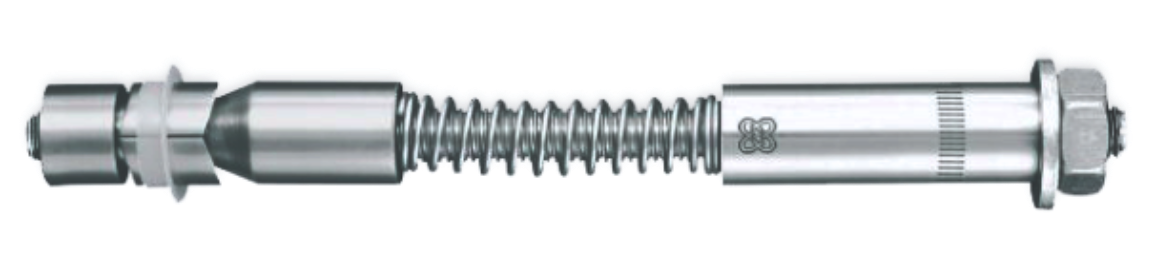

We refer to the diameter first – ranging from 10mm to 36mm (M10 to M36). Its modular design means that lengths are often bespoke to suit a particular application – and there are many M36 variants in place that measure up to 1.5m.

Ultraplus in Action

With an ETA for cracked and uncracked concrete that includes seismic and load case fire, think of anywhere where structural and human safety is paramount; from a theme park ride to a nuclear power plant installation.

Paul Papworth is EJOT UK’s LIEBIG specialist. Recent projects that he has been engaged with include installations at a hydro power, nuclear waste and waste treatment plants, plus the installation of a nuclear-powered submarine testing bed. Paul explained:

“For the hydro power plant, M36 diameter stainless steel ULTRAPLUS anchors were used to hold down a tunnel liner in the main water inlet tunnel. Ultra-high performance anchors were needed here due to a significantly high rip force that was created by the water passing through a 90 degree inlet. These massive forces had previously ripped up the 25mm steel liner.”

“The nuclear waste plant utilised M24 x 1.2m long ULTRAPLUS. Significantly high load and safety factors, including risk of failure, were the driving factors behind specification. The length of anchor chosen meant that sub-level utilities could be avoided. Anchor performance was also enhanced, providing extra strength.”

“M36 diameter zinc plated ULTRAPLUS anchors were installed at a chimney stack on the waste treatment plant in the north of England. High loadings were present in the structure, so an immediate take up of load was required – which is one of the ULTRAPLUS anchor’s unique application benefits.”